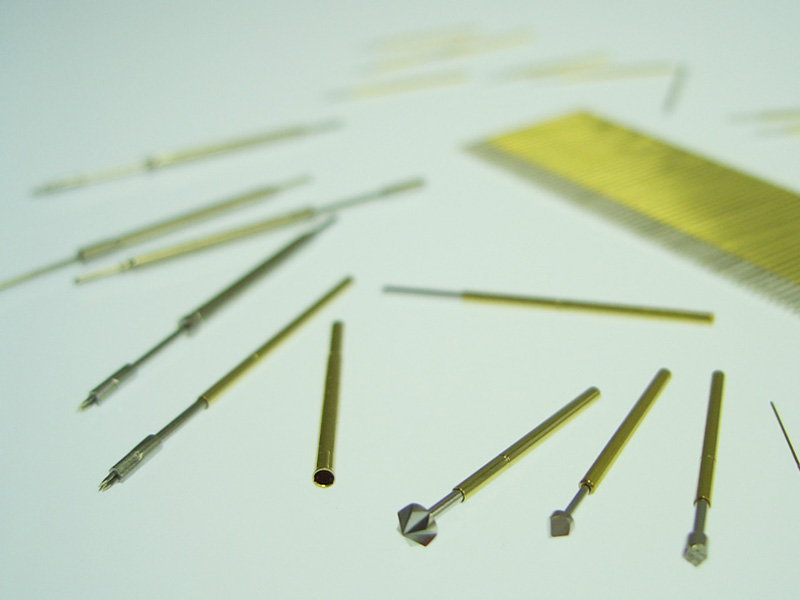

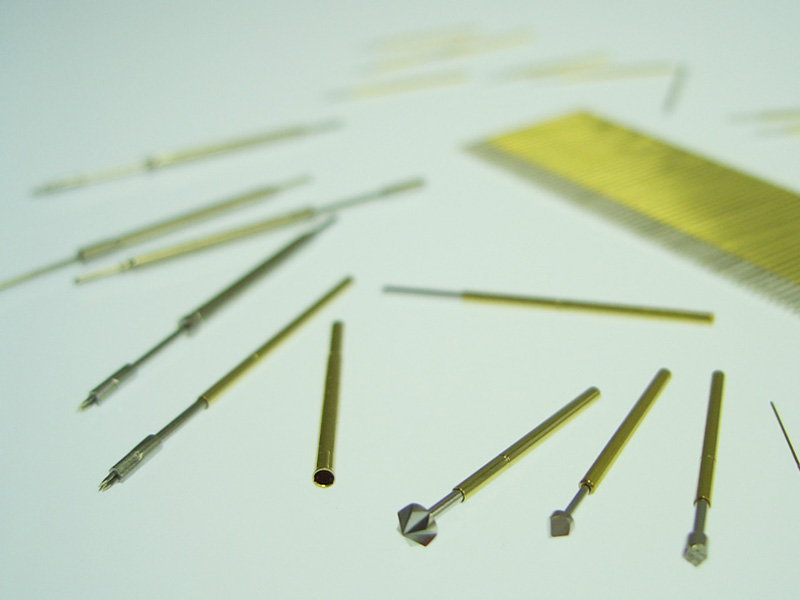

Probe pin /

Checker fixture

We manufacture contact probe pins for board inspection, switch pins,and various guide pinsused around checker fixtures.

We have a wide range of services, including metal and resin cutting, assembly, inspection, and the design and development of jigs by based on micro-precision processing technology.

Our precise and accurate

processing technology

-

Machining technology

Micron-level dimensional control technology

By incorporating the latest Swiss-type CNC automatic lathe with skilled operators, we are able to perform ultra-fine machining with an outer diameter of less than φ0.1 millimeters. The operators themselves undertake a seamless process, from program creation to tool fabrication, enabling the high-precision machining of metals and various engineering plastics.

-

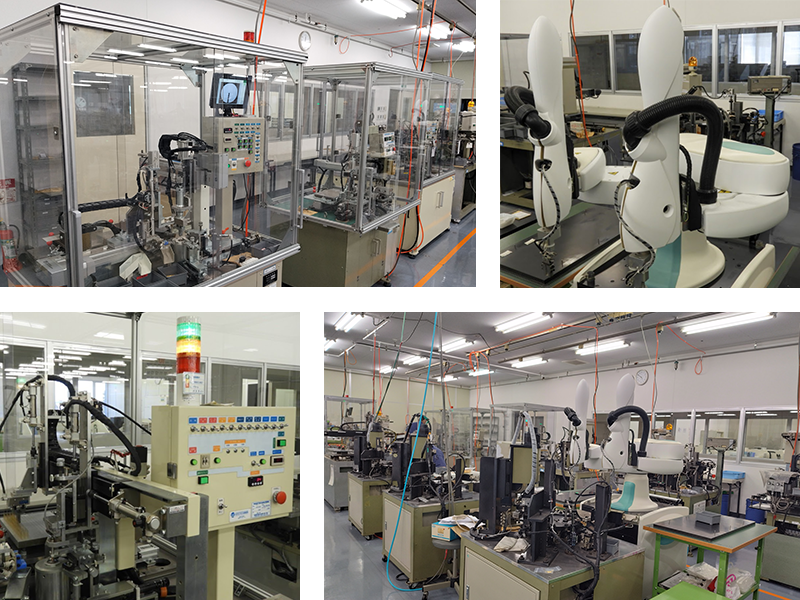

Assembly processing

For all custom orders,

flexibly respond,

conducting all assembly processesWe conduct assembly for small lot prototype products through manual operations, while efficiently utilizing automated assembly machines for large quantity production. This allows us to flexibly adapt to various production volumes.

-

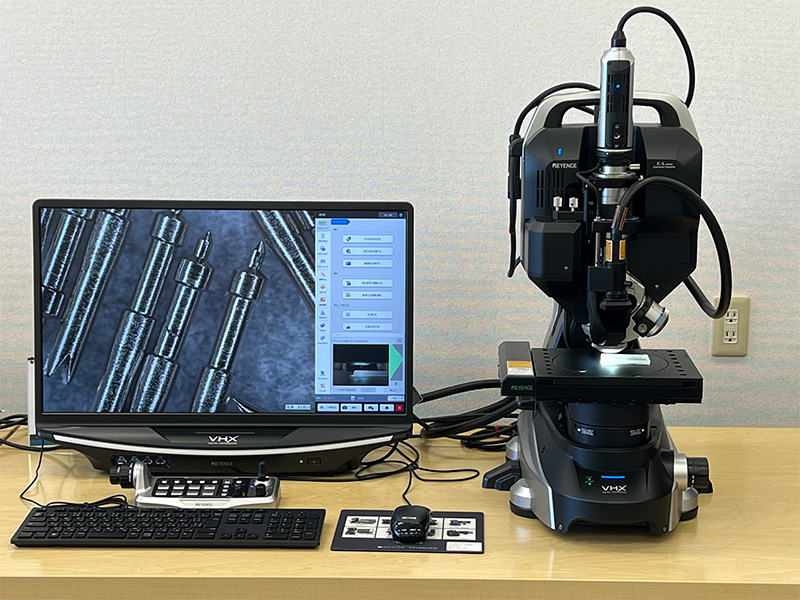

Quality control

From assembly to inspection,

One-stop productionWe actively introduce the latest inspection machines and measuring instruments, and conduct quality control in a high-quality environment.

By concurrently conducting inspections and assembly processes for the product, we have maintained a high yield and shortened the time until shipment.

Facility information

-

Machine tools

CNC Swiss-type automatic lathe

(φ0.7~φ25)63 units CNC composite lathe (φ65) 2 units Machining center 20 units PCB drilling machine 2 units General-purpose lathe 2 units Universal vertical milling machine 4 units Universal horizontal milling machine 2 units Turret lathe 1 unit Drilling machine 11 units Bench lathe 37 units Grinding machine for tungsten carbide 3 units Grinding machine for micro drill 1 unit Grinding machine for drill 3 units Thread rolling machine 1 unit Benchtop chamfering machine 4 units Right-angle planer 1 unit Running saw 1 unit Mini band saw 1 unit Cutting machine 3 units Laser marker 1 unit Barrel polishing machine 7 units

-

Specialized machine

Parts alignment machine 4 units Automatic assembly machine for probe pin 6 units Semi-automatic assembly machine for probe pin 5 units Automatic detent pointing machine for receptacle 2 units Semi-automatic detent pointing machine for receptacle 3 units Automatic assembly dual-arm robot 1 unit

-

Inspection/measuring

equipmentProjector 3 units Measurement microscope(×40) 1 unit Measurement microscope(×75) 1 unit Measurement microscope(×30-200) 4 units Measurement microscope with camera

(×200)2 units Optical microscope(×20) 8 units Optical microscope(×8-35) 1 unit Optical microscope(×8-40) 8 units Optical microscope(×8-50) 4 units Optical microscope(×10-63) 1 unit Video magnifier(×400) 2 units Electron microscope(×2000) 2 units Laser elemental analyzer 1 unit Laser scanning micrometer 1 unit Vickers hardness tester 1 unit Image dimension measuring machine 1 unit 3D shape measurement machine 1 unit X-ray transmission device 1 unit Precision resistance value/load measuring device 2 units Push-pull gauge 8 units Probe durability testing machine 4 units Insulation/withstanding hitester 1 unit Surface roughness measuring instrument 1 unit

Production factory

-

Kazusa Academia Factory

Main handled products

Contact probe pin

Probe pin for wire harness

Metal and Plastic Machined Products

Checker Fixtures

-

2-6 Kazusa-Koito, Kimitsu City, Chiba 292-1149, Japan

(〒292-1149千葉県君津市かずさ小糸2-6)

- (0439)70-1051

- (0439)70-1058

- TOP

- Probe pin / Checker fixture